AdvantagesProfessional Customized, 15-20 Minutes Drying Time, Continuous Drying Process, Reduced Dust Emissions, Lighten odor of exhaust air, Compact Structure & Less Land Occupation.

【Production Period】: Within 45 Working Days

【Processing Capacity】:As need.

【Exhaust Air Treatment】: Deodorization Device

【Fuel Choice】: Coal, Waste Wood, Biomass Pellet & Briquette, Diesel, Natural Gas, LPG, etc.

With the help of Specially designed Poultry Manure Dryer Machine by Sunco Machinery, poultry manure can be dried and converted either into organic fertilizer or biomass fuel.

With the help of the Sunco Machinery Poultry Manure Dryer Machine, poultry manure can be dried throughout the year and converted either into organic fertilizer or biomass fuel. Dried poultry manure is an excellent and frequently used plant nutrient, both in a dried form and as a pellet.

Sunco Machinery poultry manure dryer machine not only can be used to dry the fermented or compost chicken manure with moisture content about 40-50%, but also can be used to dry the fresh chicken manure with moisture content up to 75% directly. After the poultry manure drying process, the moisture content of dried poultry manure can be about 13-15% or as customers need.

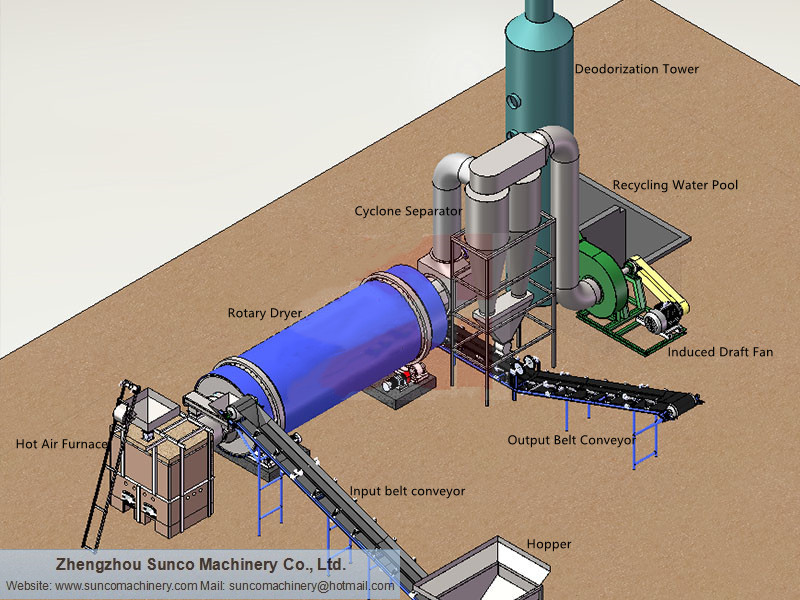

Working Princinple of Poultry Manure Dryer Machine:

Sunco Poultry Manure drying machine is to use high temperature air to heat and dry wet poultry manure continuously and quickly, and within about 15-20 minutes the chicken manure become dry. Hot air furnace system is used to burn the fuel, working together with draft fan to supply high temperature air for the poultry manure drying process. The customers can select the most economical fuel such as coal, waste wood, Palm kernel shell, corn cob, wood chips, diesel, or natural gas, etc.

Sunco Poultry Manure Dryer Machine is specially designed according to the features of poultry manure (sticky & high humidity). Its inner crushing shaft and lifting plates disperse the chicken manure, increase the heat contact area so that hot air can heat and dry chicken manure throughly. The poultry manure dryers size (diameter & length) supply the drying space and water evaporation space. By adjusting the poultry manure drying machine rotation speed, to control the drying time as need.

Deodorization system consists of deodoriztion tower, water pump, recycling water pool, condensor. It can lighten the odor of exhaust air significantly, so that the workers can bear it, reduce the complaints from the local residents, and can follow the environment protection standard.

| Model | Input Capacity (T/H) | Input M.C.(%) | Output M.C.(%) | Total Power (KW) | Heat Consumption (Kcal/hour) |

| SCM1112 | 1.0 | 70-75% | 13-30%(adjustable) | 22 | 450,000 |

| SCM1312 | 1.5 | 24 | 680,000 | ||

| SCM1316 | 2.0 | 37 | 910,000 | ||

| SCM1515 | 2.5 | 50 | 1,150,000 | ||

| SCM1518 | 3.0 | 52 | 1,460,000 | ||

| SCM1718 | 4.0 | 66 | 1,820,000 | ||

| SCM1918 | 5.0 | 74 | 2,270,000 |

For the detailed solution and price of related drying machine, please leave a message here, or contact mobile phone:+86-15838214261.