Waste wood fired hot air furnace is specially designed by Sunco Machinery, and the hot air stove is used to generate and supply high temperature flue gas for the wood chip drying machine.

Waste wood fired hot air furnace for wood chip dryer machine consists of fuel burning chamber and fire-proof & ash settling chamber. The fuel burning chamber is used to burn the waste wood, and the fire-proof & ash settling chamber is used to collect the ash and also get rid of fire sparks so that to avoid the fire possibility inside the dryer machine.

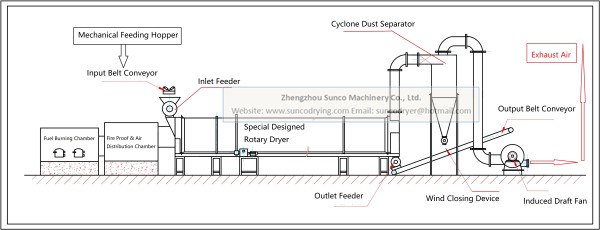

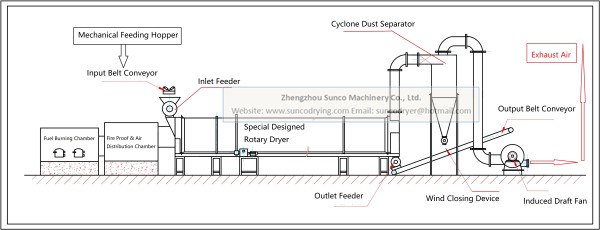

1. Hot Air Furnace: To burn the fuel and generate hot flue gas for the wood chip dryer machine.2. Mechanical feeding hopper: To store and feed wet wood chips evenly.

3. Inlet Belt Conveyor: Feed the wet wood chips into the wood chips drying machine through inlet feeder.

4. Rotary Wood Chips dryer: Disperse and heat the wet wood chips, help the hot flue gas to heat and dry the wood chip sufficiently, and get rid of the moisture from wood chip, and reduce the moisture content to be less than 20% as need.

5. Cyclone Dust Separator: To separate the fine dust from the exhaust air.

6. Induced Draft fan: To make the hot flue gas into the wood chip drying machine, and make the exhaust air and water vapor out of the dryers in time.

7. Outlet belt conveyor: to take the dry wood chip out of the dryers and send it into product storage area.

8. Electric Control Cabinet: to control the whole wood chip drying system.

Wood Chips Dryer can dry the moisture content 40%-55% wet wood chips. After the drying process, the moisture content of wood chips can be less than 20%. The dried wood chips can be used to make biomass fuel, etc.

Email : suncodryer@hotmail.com

Mobile/WhatsApp: +86-15838214261