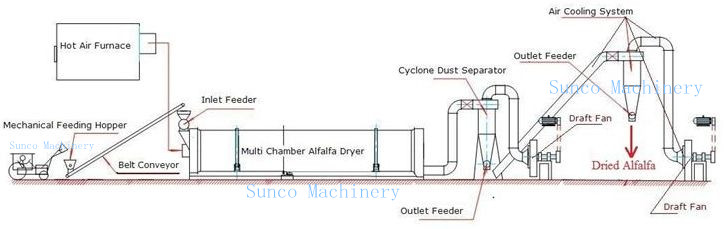

Alfalfa Drying Plant mainly consists of alfalfa knead machine, alfalfa dryer, burner, hot air furnace, air duct tube, induced draft fan, cyclone separator, chimney, electric control panel, etc.

1. Alfalfa Knead Machine is used to crush the fresh alfalfa into small pieces less than 10cm ,so that when the alfalfa dryer machine is working, the stem and leaves can have similar drying speed, and finally get stable quality dry product.

2. The small size wet alfalfa is fed into the alfalfa dryer by belt conveyor working with rotary airlock valve.

3. Hot air furnace by burning the fuel to generate and supply hot flue gas for the

alfalfa dryer process. The fuel for the hot air furnace is according to the actual situation, usually the clients can select the most cheapest one, and we can supply the related furnace system accordingly.

4. There are two induced draft fan, one is located in the front of the dryer which is used to make hot flue gas into the alfalfa dryer, and the another one is used to make the dried alfalfa and water vapour out of the alfalfa dryer in time.

5. Inside the cyclone separator, the water vapour is separated from the dried alfalfa. The water vapour goes into atmosphere through the induced draft fan, and the dried alfalfa fall down and go out through the rotary airlock valves evenly, and falls down onto the belt conveyor.

6. Belt conveyor sends the dry alfalfa into bagging machine or bale machine.

7. Electric control panel is used to control the whole

alfalfa drying plant.

*** Email: suncomachinery@hotmail.com

*** Tel./WhatsApp: +86-15838214261