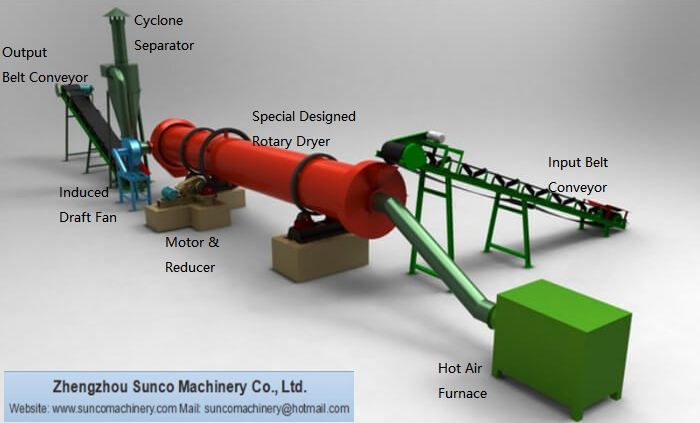

Applications of Rotary sawdust dryer machine:

The output of the drum type sawdust dryer machine is different according to the moisture of the raw materials. The smaller the moisture content of the material, the larger the output of the dryer machine. The diameter of the rotary drum can be different and we can customize it for you. What is more, the rotation speed of the drum is adjustable. The higher the dryer rotation speed, the less the sawdust drying time in the sawdust dryer.

Rotary sawdust dryer machine is commonly used in the charcoal production line for drying the sawdust at the first step, then the dried sawdust which usually with a moisture content of less than 10% will be extruded by the sawdust briquette machine.

Rotary sawdust dryer machine has a large processing capacity, less fuel consumption, and low drying cost.

The drum dryer machine adopts the structure of an adjustable center tugboat, which is well-matched with the rolling ring and greatly reduces wear and power consumption.

Sawdust dryer machine is specially designed with block wheel structure, greatly reduce the horizontal thrust caused by the tilt of the equipment. Strong overload resistance, cylinder running smoothly, high reliability.

The sawdust drying machines has the advantages of high-temperature resistance, can use high-temperature hot air for rapid drying of materials. Strong expansibility, the design takes into account the production margin, even if the output increases slightly, there is no need to replace the equipment.

Rotary sawdust dryer machine lifting plate distribution and the angle design is reasonable, reliable performance, so the heat utilization rate is high, uniform drying, cleaning materials fewer times, easy maintenance.

Email: suncomachinery@hotmail.com

Mobile/WhatsApp: +86-15838214261