For the fresh chicken manure, its moisture content is up to about 70-80%, and it is rather wet. Without drying, it can not be used as fertlizer, animal feed, etc.

For the chicken manure dryer machine, its main funtions is not only to get rid of the water, but also sterilize the worms, bacterials, etc.

As the fresh chicken manure is with high humidity, if directly to use

poultry manure dryer, to process 1000kg wet manure, needs to get rid of 700kg water.

Thus it will consume much fuel to creat the related heat needed, and the fuel consumption cost is high.

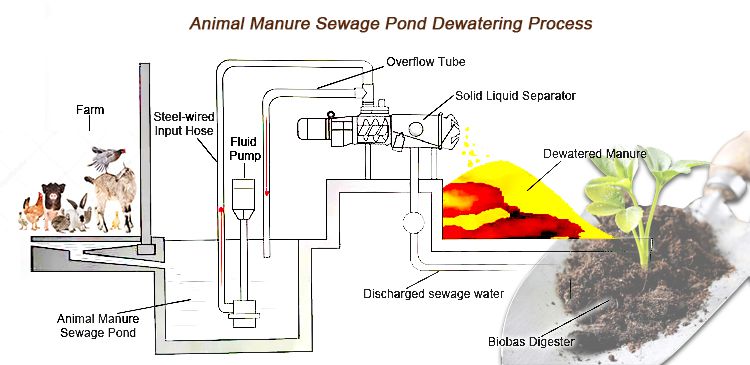

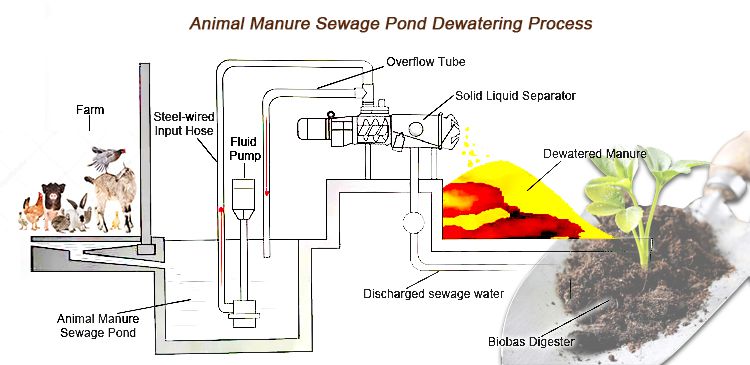

In order to save fuel consumption, it is suggested to use dewatering machine to reduce the moisture content of wet chicken manure to be less than 60% before to be dried by chicken manure dryer machine.

Then we need to use the chicken manure dewatering machine to dewater the wet manure in advance, and after that we send the chicken manure into the

chicken manure dryer.

To do it in this way, it can help to save much fuel cost. For example, when input moisture content of wet chicken manure is 60%, and the final moisture content is 20%, the to dry 1000 kg wet manure, needs to get rid of 500kg water.

Compared to use the chicken manure dryer machine to process fresh manure directly, about 200kgs water is less which needs to be got rid of. In other words, we can have more dry manure, meantime with less fuel consumption.

For detailed solution of Poultry Manure Dryer Machine, please feel free to contact Sunco Machinery by:

>>> Email: suncomachinery@hotmail.com

>>> Mobile/WhatsApp: +86-15838214261