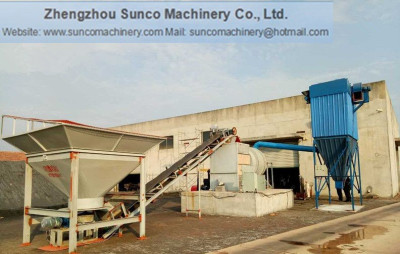

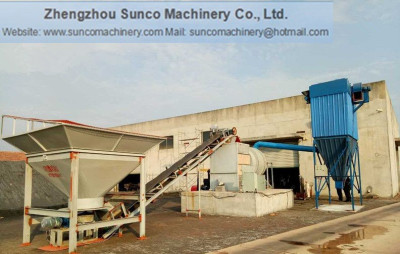

Industrial Sand Dryer Machine is used for the bulk drying of wet sand, and for different capacity, the related size of the dryers are very different.

Cylinder dryer is charactered with compact form, covering little area, needing half area compared with the same output of single dryer, reliable work, low energy consumption, high thermal efficiency, good effect on materials drying, easy to realize automatic control, requiring few operators.

Main Functions of Industrial Sand Dryer:

Silica Sand Dryer is mainly used for the drying of particle materials within a certain range of humidity, such as yellow sand used in dry mortar industry, various specifications of sand in foundry industry, blast furnace slag cement in building materials industry, small size clay, for chemicals no changes in chemical industry, the small granular materials that is not afraid of high temperature and dust.

According to the requirement in last water content after drying material in different industries, the material after drying, the water content can meet below 1-0.5%.

Industrial Silica Sand Dryer Work Flow:

Wet sand---> Hopper---> Disc Feeder--> Belt Conveyor--> Silica Sand Dryer (Hot Air Furnace supply the hot air for the sand dryer) ---> Belt Conveyor--> Vibrating Screen ---> Dried Sand.