The popular and common sand dryer are rotary sand drying machine which was developed and optimized from rotary drum dryer, and sand dryer machine can dry all kinds of sand such as silica sand, river sand, yellow sand, quartz sand, slag, mineral powder, etc with large drying capacity.

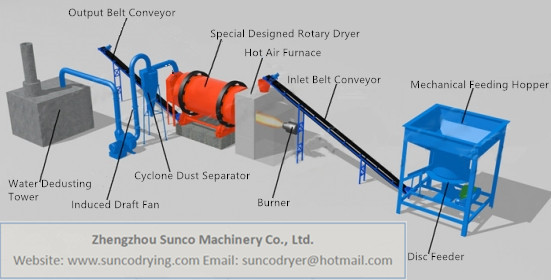

Specially designed Hot Air Furnace for the Rotary sand drying machine is to burning the fuel and genetate hot flue gas for the dryers. The fuel for the hot air furnace can be waste wood, coal, diesel, natural gas, wood chips, wood pellet, corn cob, palm kernel shell, etc. The customers can select the most cheap fuel as actual situation.

Input belt conveyor or bucket elevator to send the wet sand into the drum of rotary sand dryer.

On the inner wall of the rotary drum, there are many lifting plates and guide plates which is welded with special angle. When the Rotary Sand Dryer's drum is rotating, these lifting plates makes the sand up and down to mix with the hot flue gas sufficiently and completely. Durng this process, the moisture in the sand is evaporated into water vapor and to be taken away by the flue gas.

There is one induced draft fan is used to make the hot flue gas into sand dryers, and after the drying process, sucks out the exhaust air and water vapor, and finally the exhaust air and vapor goes into the cyclone dust separator.

In cyclone dust separator, the fine dust inside exhaust air is separated out, and falls down and goes out through the wind closing device. The exhaust air and vapor goes into atmosphere directly through the chimney.

Output belt conveyor takes out the dry sand from the sand drying machine, and send it to the product storage area.

Email: suncodryer@hotmail.com

WhatsAPP/Mobile: +86-15838214261