AdvantagesCompact Structure, High work efficiency, easy operation and maintenance, stable and durable.

【Production Period】: Within 15 days

【Processing Capacity】:As need.

【Exhaust Air Treatment】: Without

【Fuel Choice】: Without

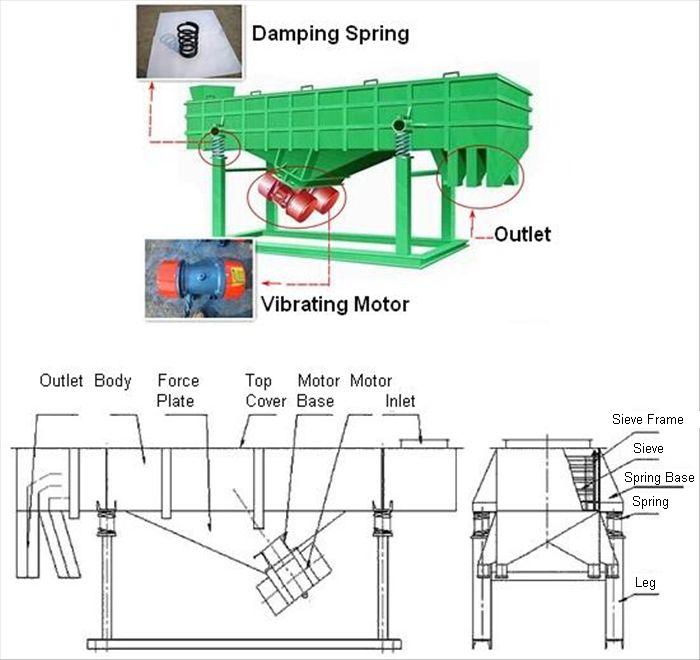

Linear Vibrating Screen also is called Linear Vibrating Sieve. It is suitable for screening powder, granular material with size up to 325 mesh.

Linear vibrating screen is designed with dual-vibration motor drive,two synchronous motors are reversely placed so that the exciter generate reverse excitation force, the exciting force generated by eccentric block cancel each other out on the parallel direction of motor axis,and stack together with the perpendicular direction of motor axis, so its trajectory is linear. Linear vibrating screen is suitable for particle size and the maximum size should be less than 10mm.

► Less energy consumption,lower noise,longer service life.

► The beam and screen box are connected by high strength blot without welding.

► High accuracy screening efficiency,simple and stable structure, convenient maintenance.

► Suitable for rough screening with high capacity.

► Long travel distance for materials on the screen surface, high screening efficiency.

| Type | Layer | Sieve Dimension (mm) | Sieve Mesh (mesh) | Particle Size(mm) | Capacity (t/h) | Power (kW) | Double Amplitude (mm) | Frequency (r.p.m) | Screen Angle (degree) |

|---|---|---|---|---|---|---|---|---|---|

| ZS-520 | 1-5 | 500X2000 | 2-325 | <20mm | <5 | 0.37x2 | 6-10 | 1460/960 | 0-10 |

| ZS-525 | 1-5 | 500X2500 | 2-325 | <20mm | <8 | 0.37x2 | 6-10 | 1460/960 | 0-10 |

| ZS-612 | 1-5 | 600X1200 | 2-325 | <20mm | <3 | 0.37x2 | 6-10 | 1460/960 | 0-10 |

| ZS-1020 | 1-5 | 1000X2000 | 2-325 | <20mm | <12 | 0.75x2 | 6-10 | 1460/960 | 0-10 |

| ZS-1025 | 1-5 | 1000X2500 | 2-325 | <20mm | <16 | 0.75x2 | 6-10 | 1460/960 | 0-10 |

| ZS-1030 | 1-5 | 1000X3000 | 2-325 | <20mm | <20 | 1.1x2 | 6-10 | 1460/960 | 0-10 |

| ZS-1224 | 1-5 | 1200X2400 | 2-325 | <20mm | <23 | 1.5x2 | 6-10 | 1460/960 | 0-10 |

For the detailed solution and price of related drying machine, please leave a message here, or contact mobile phone:+86-15838214261.